How To Guides

How to Install Roof Ventilation and How it Works

When looking at roof ventilation it’s important not to confuse it with uncontrolled air leakage. Ventilation ensures that a building’s internal environment is supplied with adequate fresh air and allows it to move in a controlled way. This is becoming an increasingly important element of Building Regulations in the quest to ensure we provide greater thermal efficiency.

Product selection

Underlays

You will probably be aware that all vapour permeable underlays (VPUs) should now be used with additional, supporting high level ventilation. It’s something which the NHBC made clear nearly two years ago following a steady and unsustainable increase in the number of roofing-related claims under its 10-year Buildmark warranty.

Browse our range of underlays here.

Tip

The only underlays which do not need supply supporting high level ventilation are those classified as ‘air-open’. Only four such products are currently available, one being Klober Permo air. However, some companies are still saying that their VPUs can be used to provide the sole means of ventilation. THIS IS SIMPLY NOT TRUE!

Choosing and installing the underlay

Klober offers a choice of VPUs including specialist products for metal roofs and wall ventilation. For roofs, the 4-layer Permo forte will be known to many customers of JJ Roofing as it has been tried and tested over many years and provides a high standard of ventilation, wind uplift resistance and durability.

Though it should not be used to encourage unsafe working, it’s worth pointing out that Permo® Forte provides added protection against falls through rafters. Unlike lightweight underlays which offer virtually no fall resistance whatsoever, it has a built-in safety mesh.

For airtight roofs, Permo forte SK2 also has integral edge tapes to seal laps and make installation quicker.

You don’t have a great deal to worry about when installing an underlay as it is marked which side up it should be laid. What is often forgotten is how important it is to install an underlay with the correct drape between rafters. This should be a nominal 10mm below the level of the batten to ensure that moisture is allowed to run down the underlay to the eaves. Permo Forte offers exceptional tear resistance and the temptation is simply to pull it taut as you staple it into position.

Battens are installed allowing the roofer to work up the roof and the width of a lap depends to a large degree on the pitch. The lower the pitch the wider the lap should generally be. Counter battens are also used if a roof is to be fully boarded with either insulation or sarking. The counter batten must be at least 10mm thick to allow moisture to pass beneath it to the eaves or, if the space between the underlay and tile needs to be ventilated it should be 25mm or more.

Tips

- Permo forte SK2 offers the added benefit of having self-adhesive edge strips which enable laps to be sealed. If you are working on a roof which has been designed to be airtight this avoids the need to fix a specialist airtightness tape separately.

- Leave at least a 5mm continuous gap in the underlay at the ridge.

Supporting high level ventilation

Ventilating dry ridge

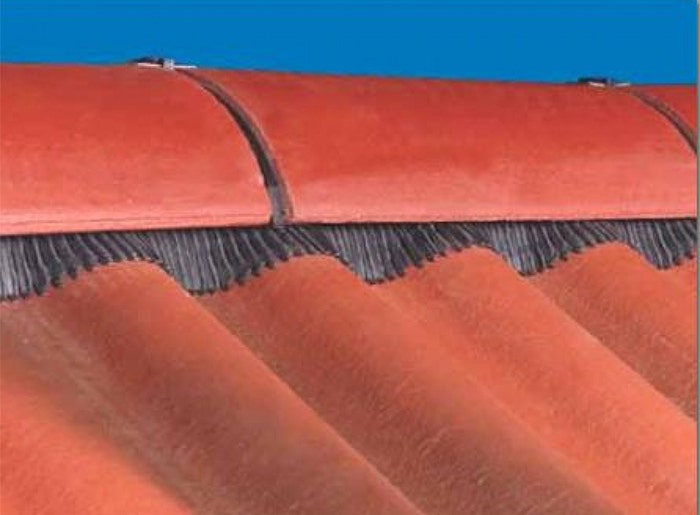

Once your underlay is in place, supporting ventilation at or near the ridge is used as part of the tile / slate fixing process. This can take the form of a ventilated dry ridge system or traditional tile or slate vents. For many, the easiest option is to use a ventilating dry ridge such as Roll-Fix® as it contains all you need to fix 5 metres of ridge or hip

Roll-Fix is particularly useful as, unlike most dry fix systems, it uses a single ridge seal for either half-round or angle ridges. Hip kits also contain hip trays and cro clips

Tip

Of the many dry ridge systems, some perform poorly due to the quality of self-adhesive backing on the ridge roll. Roll-Fix has a Butylon® backing which has been proven to provide a strong, immediate and permanently weatherproof bond.

Traditional tile and slate vents

For many years traditional tile vents were a standard feature of everyday roofing. Unfortunately, many were unsightly and suffered from discolouration due to the effects of UV and this was one of the reasons why vapour permeable underlays became popular so quickly. As an alternative to a ventilating dry ridge, modern vents such as those in the Klober Profile-Line® range follow the line of the tile used on the roof.

So, whether you are fitting a Double Roman, a single pantile or a 15 x 9, there’s a Profile-Line vent you can use for most concrete interlocking roof tiles in a colour to suit. All are virtually unseen on the roof and have been designed for universal use so, whoever’s tile is being installed, a Klober Profile-Line vent will do the job. They can be used at high or low level and with soil ventilation or mechanical extraction outlets too.

If fitted towards the ridge at least one full course of slates must be fitted above the head of the vent. Similarly, if fitted at the eaves, they also need at least one full course of slates below the vent to allow free air flow. If in doubt, Klober provides at-a-glance diagrams which explain what ventilation requirements you need.

Tips

- Take particular care with low pitch roofs. It’s a good idea to call a specialist such as Klober for confirmation of what you will need.

- Remember, the ventilation set out in BS 5250 is the minimum needed to ensure condensation in the roof space is adequately dealt with.